Uncategorized

Making Castile Soap / Using Our New Custom Molds

The soap business has been going well, and the soap molds we’ve been using for the past 3 years have become a little small… so a couple days ago the UPS driver delivered 4 beautiful custom slab molds and one handy-dandy log splitter! After extensive research we selected For Craft’s Sake, a small business in Minnesota, to make our molds.

Each custom mold will produce 4 logs that are equal in size to our current logs, so each mold will make 44 bars as opposed to the 11 bars each of our molds currently makes. This tutorial is the story of the maiden voyage of our new molds, and the making of one of our finest soaps, pure castile soap made with organic olive oil. (And if you think a certain “doctor” makes real castile soap, um, no not so much).

Castile soap dates back to the days of the Crusades, and originated in Spain. The story goes that the finest soap in the world was made in Aleppo (the very same place that is sadly besieged) using olive oil and laurel berry oil. When the crusaders pushed into Spain there was no available laurel berry oil, so a soap was created using only olive oil. True castile soap is white (or very light green), hard, long lasting and extremely gentle. To reach perfection a cold processed castile soap must be aged for 6 months or more, so the soap in this tutorial will not be available for sale until sometime late spring or early summer of 2017. Now that’s advance planning!

To start with the soapmaking process we measured out over 10 lbs of extra virgin organic olive oil, and mixed our lye solution which we allowed to cool to room temperature. Then we added the lye solution to the oil and stick blended, took a break to wrap soap, stick blended some more, fixed supper, stick blended a while longer, and finally the mixture began to thicken and reached a very light trace.

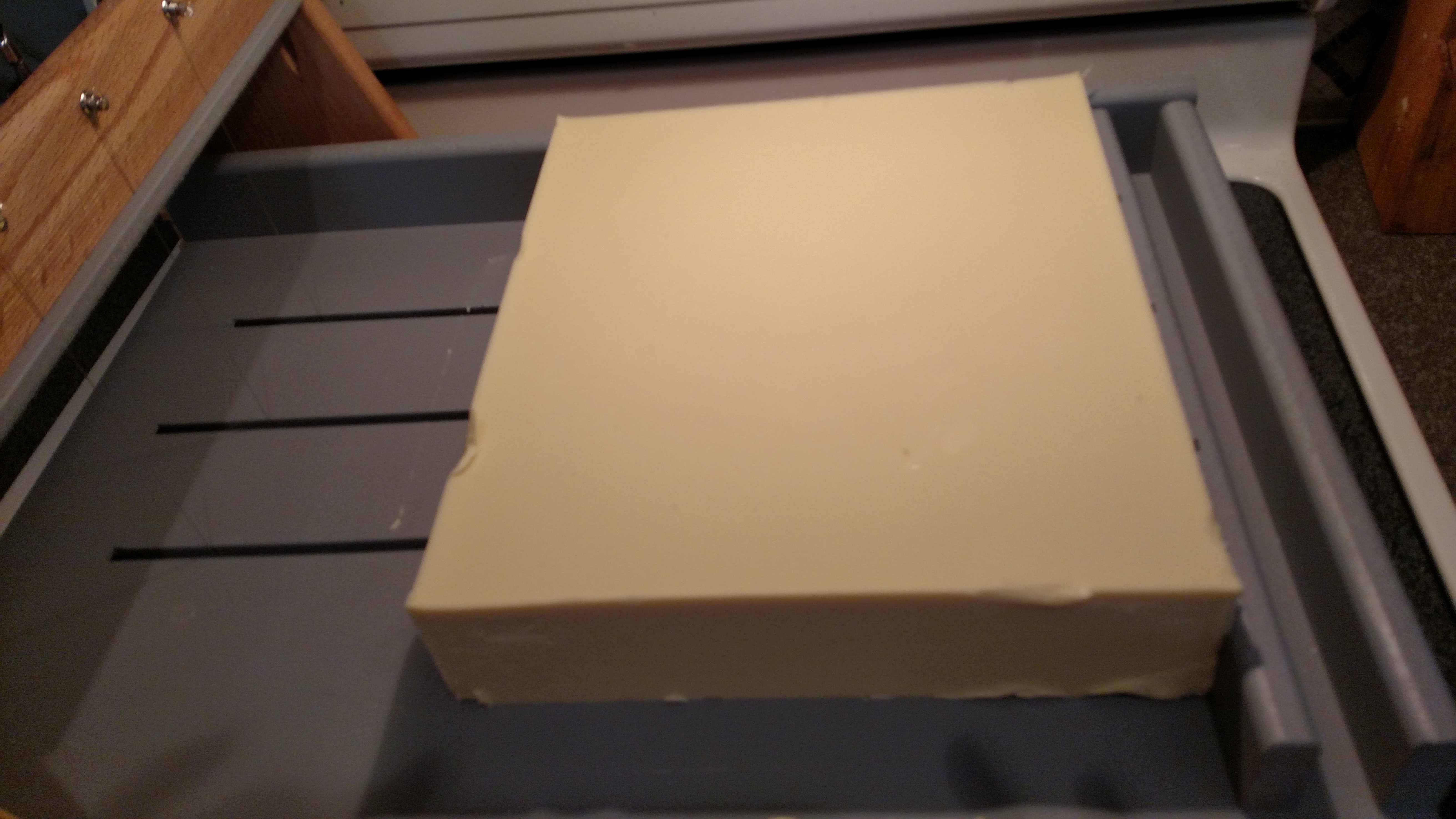

Then we poured the soap into the mold, and put it away to rest for 48 hours and waited patiently.

After unmolding our block of soap it is transferred to the log splitter to be cut into 4 soap logs. Each log will then be cut into 11 individual bars. Our recipe for castile soap is simple, just organic olive oil, purified water and lye (sodium hydroxide). We recommend purchasing your organic olive oil from a trusted supplier, many extra virgin olive oils are not pure, they may contain oils obtained from the second pressing of olive oil, or worse, oils that are not olive oil at all.

We are including our recipe to allow you to see our ingredients. We do not recommend making soap in this size batch unless you have had successful experience making smaller batches.

Recipe:

168 oz. organic olive oil

33 oz. purified or distilled water

21.3 oz. sodium hydroxide

Purchase Daisy G’s Castile Soap made with 100% Organic Olive Oil here.

Please feel free to ask questions in the comment section. Thank you!